- MESHCAM 6 PROGRAM ZERO ISSUE HOW TO

- MESHCAM 6 PROGRAM ZERO ISSUE INSTALL

- MESHCAM 6 PROGRAM ZERO ISSUE DRIVER

- MESHCAM 6 PROGRAM ZERO ISSUE REGISTRATION

- MESHCAM 6 PROGRAM ZERO ISSUE SOFTWARE

This option requires very accurate tool holders that keep the length constant and a lot of effort on your part to measure and input all of the length data before machining begins. In many machine controllers it is possible to preconfigure everything so that a tool change doesn’t require a rezero. You need to touch off that corner again except that it isn’t there: Nor you’ve finishing roughing and you’d like to use a different tool for the finishing. Image that you’ve set the zero on the top, southwest corner as seen below: If the point initially used has been machined away by the roughing operation then you’ve lost the ability to set your tool length. The point you pick for a zero must be available any time you need to do a tool change and reset the tool length. If you change tools in the middle of a machining job then you need to reset the Z value of the zero since the two tools are not likely to be exactly the same length. The only time the “Top Southwest” position may give you trouble is when you need to change tools… What about tool changes?Īll of the coordinates in the gcode file tell the mill where to move the tip of your tool. Z coordinates will be negative when you’re cutting into the stock and any positive Z number should be “in the air”. In general, this is what I use 90% of the time it works well, it’s easy to locate and it keeps all of the X and Y toolpath coordinates as positive numbers. If I had to give you one default position to pick it would be the top of the stock, in the lower left-hand corner, the southwest corner in MeshCAM terminology. While this zero may take a few minutes for a new machinist to locate, it’s not hard to do if you’re patient. While this is a point that does exist, it’s in empty space so you have very little change of accurately finding it.īy contrast, if you were to pick a corner of the stock then you have three planes/sides that you can touch the tool off of, the top, side, and front. Imagine, for instance, a zero that was 10 inches to the left of the bottom corner of the stock. For you, the machinist, the program zero must be something you can locate with the mill if the point cannot be located then you are probably going to have a lot of problems. On a mathematical level, the CAM program can accept any arbitrary zero point, it’s just an offset in space and one is as good as another.

MESHCAM 6 PROGRAM ZERO ISSUE SOFTWARE

The program zero also gives the CAM software a single reference point for the toolpath.

MESHCAM 6 PROGRAM ZERO ISSUE REGISTRATION

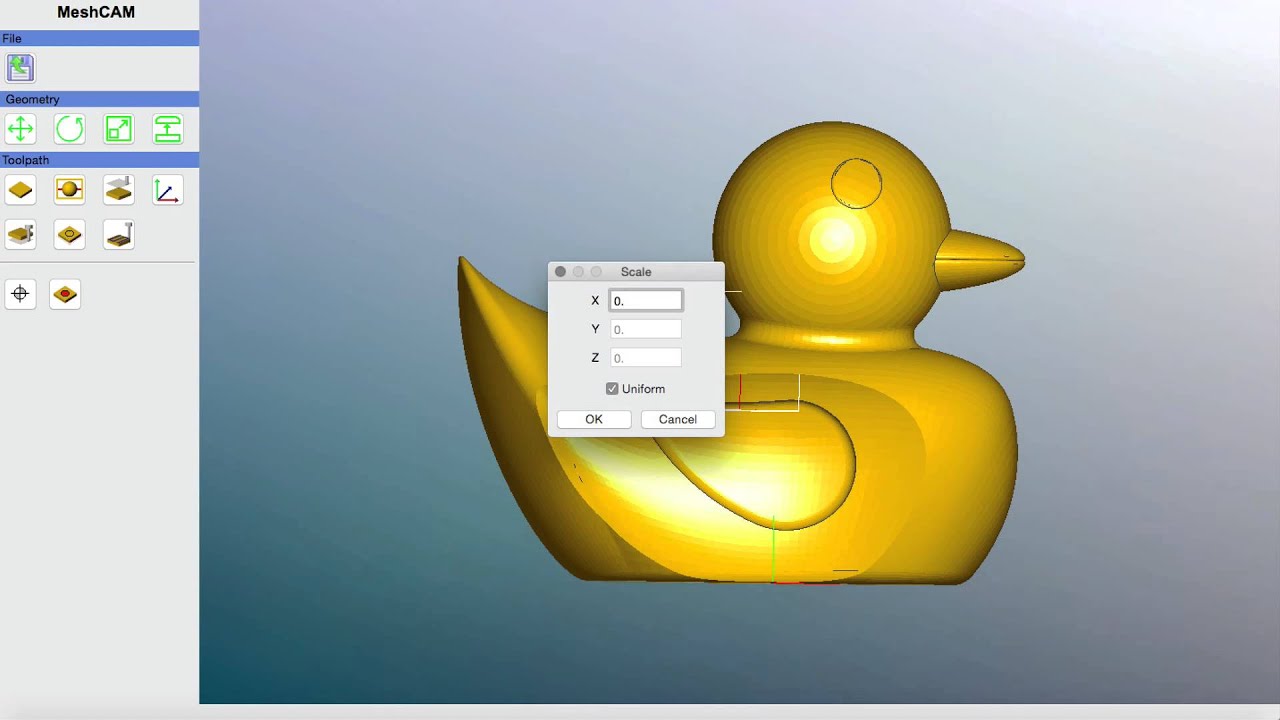

Without this registration process, there is very little chance that anything would line up. Since the mill table is generally much bigger than the stock you are cutting the mill must be “told” where you’ve put the stock. This can be seen more clearly in the image below:Īt a basic level, the program zero tells the mill where to find the stock on it’s table. MeshCAM uses the compass layout- north, south, east, and west, to describe the location.

It’s difficult to write clearly about sizes and edges when we talk about the location of the zero. My one caveat for this post is that it doesn’t apply equally to everyone if you have a big machining center with an automatic tool changer and properly configured tool offset tables then this doesn’t apply to you as much. Once you get a few jobs done and get a better understanding of the process there are real benefits to picking the right program zero for a job. Luckily, the default program zero in MeshCAM is very safe, and most users begin with very forgiving jobs, so everything usually works out fine. Most will just accept the defaults and see what happens.

MESHCAM 6 PROGRAM ZERO ISSUE HOW TO

NET Framework 4.5.New users frequently ask questions about how to set a program zero for a toolpath. NET Framework, see the following Knowledge Base articles: NET Framework 4.6.2.įor the known issues in earlier versions of the. NET Framework 4.6.2, see Application compatibility in the.

MESHCAM 6 PROGRAM ZERO ISSUE DRIVER

Framework client driver for Always Encrypted resulting in intermittent failures to decrypt individual rowsĪpplications that rely on TLS 1.2 strong encryption experience connectivity failures after a Windows upgradeįor more information about application compatibility in the. Path.GetDirectoryName and Path.GetPathRoot do not work with URIs when you target the. NET Framework 4.6.2 and its workaround, see the following Microsoft Knowledge Base article.

MESHCAM 6 PROGRAM ZERO ISSUE INSTALL

NET Framework 4.6.2įor information about the issue that you may experience after you install the. This article lists the known issue that you may experience after you install the Microsoft.

0 kommentar(er)

0 kommentar(er)